Current processes in the construction sector are mostly carried out by using 2 dimensional models. The created “Model based planning methods” enable improved communication among the project parties, prevent planning mistakes, and allow automation of the cost calculations.

Detailed information on building elements of the built construction are needed for different requirements from the idea stage to the operational stage. During the preliminary design phase, volume data of the construction is needed for the construction site and energy analysis and during construction phase information like element quantities, procurement periods and cost data are needed. In this context, the BIM Model provides;

The possibility to plan correctly and better manage all the stages of the design.

Design coordination of all disciplines on a single model to allow for the possibility of having control of all details of the construction.

Considers all construction elements as an alternative part of the whole and develops an alternative.

Enables the construction element to be sustainable during the process by having clear information on all the construction elements.

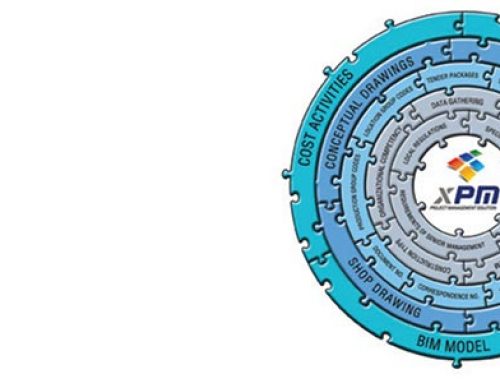

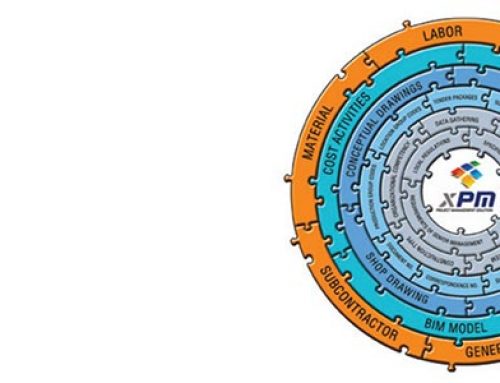

xPM AND BIM INTEGRATION VALUE ADDS

- Data produced with the design become information that is usable by the owner, contractor and business operator.

- All data collected at the time of design is saved based on versions during the project duration. (Master Plan Revision)

- Changes that occurred with revisions are reflected on all accounts and analyses. (Resource quantities, estimated cost, planning, cash flow, purchasing etc.)

- BIM (Building Information Model) is used to create a 3 dimensional information system to save data such as form, size and material for each building element.

- Quantity take off tables are calculated automatically by using this 3 dimensional model.

- Location Quantity Take Off Tables are calculated automatically from the BIM model in the frame of the Model element table rules.

- Green Book and Discovery information are quickly revised with Design Revisions.

- All quantity table changes can be saved as versions and compared.

- Errors in manual quantity take off calculation are minimized and they can be compared with the quantities calculated by using the BIM model.

- Major design mistakes are prevented. This way delays in the project duration and exceeding budget problems are minimized.

- By superposing the design data from different disciplines, conflicts between disciplines are easily determined during the design stage.

- “Value Engineering” studies are done most effectively with the help of the financial data from the archive and log projects.

- In scope of the 5th Dimension xPM -BIM integration provides;

- Profitability Analysis and Value Engineering

- End of Work Budget Projection

- Earned Value Analysis

- Business Intelligence Reports can be created with fast, accurate and up to date data and are accessible from mobile devices.

- “As-Built” projects can be created with the model providing a very fast settlement process.

- In scope of the 6th in dimension, with the help of the tender, purchasing, technical specifications, supplier data of the xPM functional modules, data to be used during the operational stage is made more effective with xPM-BIM Integration.